It helps you to run your business on top of your ERP system or your “delicate Excel ecosystem”. In both cases you probably lack a lot of IT and software functionality while executing your manufacturing plans and improvements.

MES stands for Manufacturing Execution System and being a MES Petkafy will help You in all steps of Your operational production management from scheduling the production to manufacturing data analysis and improvement.

If You have a lot of Excel files that are used to plan, report and analyse Your production or Your ERP does not provide a truly flexible and comfortable interface to create the production schedule or to analyze and visualize Your actual performance, it is time for a MES to kick in. Petkafy takes Your data and uses it the smart way, so You can have automatic visualization of any manufacturing related indicators and well explained and relevant input wherever You need it for everyday operational management or even for Your regular reporting routines.

Integrate it to Your ERP

Petkafy can operate as a self-sustained system, but in case You are already using an ERP, Petkafy can be fully integrated to Your existing system during site install, so any master data and databases You might have stay always in sync in both systems. And if You are using only Excel today or would like to use our web based platform, You will probably find our extensive standard importing module helpful in mass inputing of Your available data. The standard import tool can be used for almost any databases that You would need to run Petkafy with as little effort as possible from product master data to delivery schedules.

Petkafy can operate as a self-sustained system, but in case You are already using an ERP, Petkafy can be fully integrated to Your existing system during site install, so any master data and databases You might have stay always in sync in both systems. And if You are using only Excel today or would like to use our web based platform, You will probably find our extensive standard importing module helpful in mass inputing of Your available data. The standard import tool can be used for almost any databases that You would need to run Petkafy with as little effort as possible from product master data to delivery schedules.

Best for Processing Plastics

Petkafy has been developed in co-operation with injection moulding companies and is designed to fulfill automotive requirements among all other tasks, so it will definitely excel in planning, reporting, visualization and analysis in case Your company has a similar profile. However, as a universal system that uses simple and lean process approach Petkafy has no issues handling almost any manufacturing model.

How does it work?

Well, here is a short overview.

1. Know Your Demand (read more…)

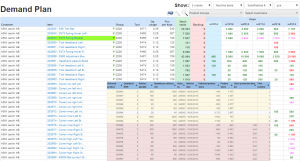

The core of Petkafy is the Demand Plan that visualizes the actual and undistorted material and products demand based on scheduled deliveries and available stock. You can create sales orders in Petkafy, sync them with Your ERP in case of site install or import the order lines from an Excel file. The plan can be rendered on weekly or daily basis and You are free to select if You would like to see the demand in delivered pieces, operator or machine hours or even the cost price of Your products.

The core of Petkafy is the Demand Plan that visualizes the actual and undistorted material and products demand based on scheduled deliveries and available stock. You can create sales orders in Petkafy, sync them with Your ERP in case of site install or import the order lines from an Excel file. The plan can be rendered on weekly or daily basis and You are free to select if You would like to see the demand in delivered pieces, operator or machine hours or even the cost price of Your products.

You will have clear overview of when You will run out of material and it does not matter if it is manufactured by Your company or purchased, because the demand plan is generated for all parts to the deepest level of the Bill of Material of Your products that You need to deliver.

2. Plan Your Production Efficiently (read more…)

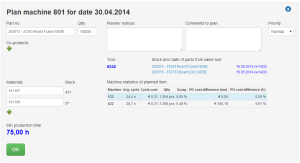

Based on the Delivery Plan Petkafy can immediately help You to prioritize the production and schedule the items onto Your machines.

Based on the Delivery Plan Petkafy can immediately help You to prioritize the production and schedule the items onto Your machines.

In case You decide to follow the default path and recommendations from Petkafy planning could be made by one click. You will be made aware of possible alternatives and ways to combine Your production during planning to allow You to minimize set-up costs based on product master data and actual reported results from previous production runs.

In many cases Petkafy is a self-learning system. For example once You introduce a co-product to a tool, Petkafy will know that the co-products are produced in one shot and therefore calculates the manufacturing efficiency and production time always correctly.

In many cases Petkafy is a self-learning system. For example once You introduce a co-product to a tool, Petkafy will know that the co-products are produced in one shot and therefore calculates the manufacturing efficiency and production time always correctly.

In the same time Petkafy is also very flexible and You can override almost any default or master data if You would like to do so. For example if You need to use an alternative material for this specific production run (say for testing or similar purposes), but keep it unchanged in the product BOM, You can simply state the alternative material while planning and this changed material will be highlighted in the Production Plan. Small, but helpful things like these are not so easy to manage in most ERP systems.

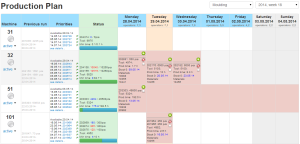

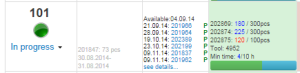

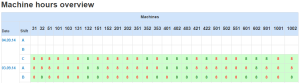

As a result of Your planning activities a visual Production Plan showing the schedule of each machine is created. This can be rendered on Your shop floor and used for actual manufacturing. The Production Plan will incorporate and provide real time feedback about the manufacturing progress based on actual reports, so You can adjust Your planning and notice any delays or even overproduction timely. Changes can be made by simple drag and drop action, of course.

As a result of Your planning activities a visual Production Plan showing the schedule of each machine is created. This can be rendered on Your shop floor and used for actual manufacturing. The Production Plan will incorporate and provide real time feedback about the manufacturing progress based on actual reports, so You can adjust Your planning and notice any delays or even overproduction timely. Changes can be made by simple drag and drop action, of course.

3. Intelligent Production Reporting (read more…)

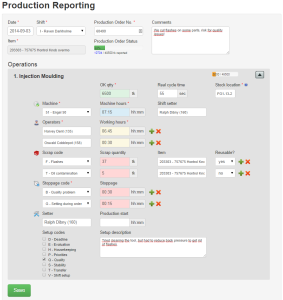

Petkafy allows You to report production directly or integrate the system with Your ERP and improve Your reported data so that it really supports Your efforts in improving manufacturing performance and waste reduction. There are no limitations on reporting scrap and rejects, stoppages or operators per production run and in case Your parts have more than one operation defined, You can report all operations at once to make the job of reporting itself as efficient as possible.

Petkafy allows You to report production directly or integrate the system with Your ERP and improve Your reported data so that it really supports Your efforts in improving manufacturing performance and waste reduction. There are no limitations on reporting scrap and rejects, stoppages or operators per production run and in case Your parts have more than one operation defined, You can report all operations at once to make the job of reporting itself as efficient as possible.

As Petkafy is developed following the Lean principles it visualizes Your production progress in real time while You type the produced quantities and highlights overproduction, so You are able to pull the break immediately. The progress of each production order is visualized right next to it in the Production Orders list and in case of questions You can navigate to the actual related production reports with just one click on the progress bar.

Your machine schedule (plan) is automatically updated with the latest data and Your production planner can see the the status of production runs next to each machine in the planning view. This way he or she does not have to look and wait for data and can take immediate actions in case of delays and notice overproduction timely too.

Your machine schedule (plan) is automatically updated with the latest data and Your production planner can see the the status of production runs next to each machine in the planning view. This way he or she does not have to look and wait for data and can take immediate actions in case of delays and notice overproduction timely too.

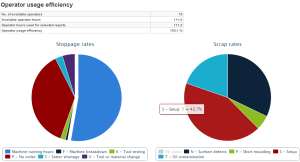

Comfortable and visual overview reports are automatically generated based on reported data that make it easy and fast to notice deviations in reporting, see significant gaps between actual reported results and planned values and take action immediately to get back on track and achieve best possible production performance.

Comfortable and visual overview reports are automatically generated based on reported data that make it easy and fast to notice deviations in reporting, see significant gaps between actual reported results and planned values and take action immediately to get back on track and achieve best possible production performance.

The statistics based on reported data is provided smartly where You need it for better production planning, but also processed and displayed visually in statistical overviews for further process analysis and improvement.

Benefits

Petkafy will automatically and in real time visualize Your actual performance and waste on graphical dashboards and help You to make reasoned decisions based on actual manufacturing data while planning as soon as You input first production reports. You will never have to process data in Excel manually again to create charts or to achieve overview of what is going on in Your company. Furthermore, the important data is shown to You right where You need it and when You need it to run Your business.

Petkafy will automatically and in real time visualize Your actual performance and waste on graphical dashboards and help You to make reasoned decisions based on actual manufacturing data while planning as soon as You input first production reports. You will never have to process data in Excel manually again to create charts or to achieve overview of what is going on in Your company. Furthermore, the important data is shown to You right where You need it and when You need it to run Your business.

- eliminate planning mistakes in the future,

- use the most efficient process for each product,

- prevent high scrap or lost machine hours,

- reduce quality risks of Your delivered products,

- push Your staff to achieve more.